Compressors are devices for compressing air or a gas and supplying it at an increased pressure, e.g. to power a gas turbine. As such there are multiple close clearance components within the compressor assembly, with small orifices that can get clogged from operational dirt, rust and debris. This clogging impairs the compressor performance resulting in increased power consumption and increased running cost.

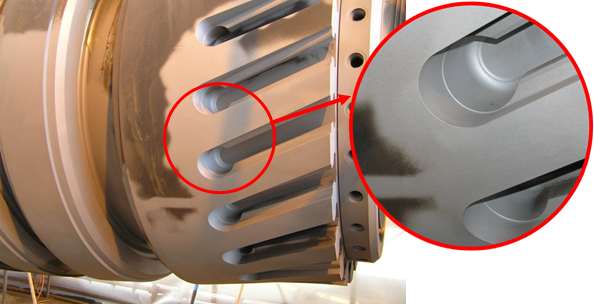

The above photo shows a compressor rotor shaft that is in the process of being sponge cleaned by Energice. Sponge cleaning was adopted for this application as the compressor was stripped down to its constituent parts.

The net result of the cleaning was a significant improvement in operational performance for the client.